The potential of coffee waste to create a wide range of products is truly remarkable, including household items and even sneakers.

Every day, British people consume approximately 98 million cups of coffee, resulting in around 250,000 tons of coffee grounds per year that often end up in landfills. To put it into perspective, that's almost the weight of 2,500 blue whales. However, according to a 2020 study by Yale University, the UK ranks 4th in the world for its ecological efficiency index, reflecting the country's environmental state and natural resource management. Other European countries also rank high in this index, and this article will provide numerous examples related to them.

We have highlighted the various byproducts generated in the coffee industry, how to reduce their quantity, and why it is crucial to do so. In this article, we will delve into the reuse and processing of these byproducts.

Beverage: What can be derived from farm waste?

At this stage, the byproducts generated include husks, parchment, pulp, and mucilage.

1) Fertilizer from pulp: During the washed or semi-washed processing, the pulp is separated from the parchment. It can be composted and used as fertilizer for coffee trees.

2) Beverage from cascara: A beverage can be made from cascara, the dried pulp of coffee cherries. It has a taste reminiscent of dried fruit compote and contains caffeine, although in lower concentrations than coffee. In our product range, we offer dried cascara for brewing and a carbonated beverage based on cascara in a can.

Construction material: Utilizing parchment in recycled plastic

Woodpecker, a company, incorporates parchment from coffee beans into recycled plastic to create a relatively lightweight and durable construction material called Woodpecker WPC, which stands for wood-plastic composite. This material possesses fire-resistant properties, longevity, and resistance to insects.

The development of coffee-plastic material by Woodpecker began in collaboration with the Universidad de los Andes in Colombia almost a decade ago. According to Alejandro Franco, the CEO of Woodpecker, one of the motivations was the urgent need for reliable and durable homes, schools, healthcare facilities, and other buildings in rural areas.

In such locations, the complex infrastructure makes it challenging to obtain and transport bricks, cement, and concrete to remote areas. Therefore, a material was required that could be strong enough for construction yet lightweight for transportation by boat, helicopter, or mules. "We chose the coffee parchment because it is stronger and drier compared to other fibers. Additionally, it can be easily ground into powder," says Franco.

Woodpecker, a wood-plastic composite, is used for constructing houses, warehouses, fences, and facade cladding. © woodpecker.com.co

Woodpecker sells the material wholesale. "In addition to exports, there is a need for social infrastructure in Colombia, especially in rural areas. The housing market requires more than 20,000 homes per year. The goal is to satisfy at least a significant portion of this demand," said Franco.

Automotive parts and waste roasting biocomposite

The main byproducts during the roasting process are silver skin and coffee chaff (quakers).

Plastic parts in cars: Ford Motor Company and McDonald's have launched a joint project. The automaker obtains silver skin from McDonald's as a supplier of roasted coffee. Typically, this waste is incinerated in landfills, but Ford Motor Company uses it to manufacture plastic components for vehicles, such as headlight parts. According to the automaker, using silver skin helps make their products approximately 20% lighter and saves up to 25% of energy during production.

"Like McDonald's, Ford aims to minimize waste, and we are constantly seeking innovative solutions to achieve this goal," said Jan Olson, McDonald's Senior Director of Global Sustainability. "Together, we have found a way to utilize silver skin as a resource. We believe we are improving each other's work to increase participation in a circular economy."

Thread for 3D printers: C2Renew has developed and patented a biocomposite composition for plastic based on coffee. The company collects waste material from both small roasters and large manufacturers. They produce plastic with varying concentrations of coffee waste, which is then used by 3dom to create thread for 3D printers. This thread can be used, for example, to make filter holders, business card holders, napkin stands, or mugs. C2Renew's future goal is to obtain permission to produce material intended for contact with food products.

Sugar-based body scrub: Quakers, the rejected coffee beans, find application in creating body scrubs. They are combined with cane sugar, grape seed oil, sweet almond oil, and shea butter to produce a body scrub.

Sneakers, watches, and biofuel: Products made from consumption waste

The main waste products at this stage include used coffee grounds, packaging, capsules, filters, cups, and other accessories.

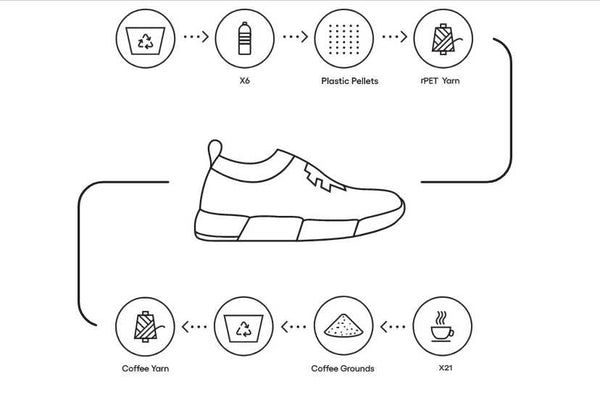

Material for sneakers - The Nomad: Rens, a footwear company from Helsinki, produces athletic shoes using recycled plastic and used coffee grounds. Sneakers made from this material repel moisture, dry quickly, and possess antimicrobial properties. Additionally, they are lightweight, flexible, and durable.

Rens sneakers are made from recycled plastic and used coffee grounds. © rensoriginal.com

"Our mission is to transform environmentally friendly materials that are widely available on the market into interesting and innovative products, extending the lifecycle of this presumed 'waste'," said Jesse Tran, CEO of Rens.

Coffee grounds cups: Coffee Kreis produces reusable Kreis Cups and Kreis Travel Cups, including the Kreis Latte Cup. These cups are made from a durable composite material that consists of approximately 30% used coffee grounds. The tableware is impact-resistant, has thermal insulation properties, and is dishwasher-safe. It serves as a great alternative to disposable paper cups. The company's products are environmentally friendly, suitable for reuse, and recyclable. At the end of their service life, old Kreis Cups can be transformed into new ones.

Kreis Cup is a reusable biodegradable cup made from coffee grounds and plant-based materials, free of petroleum-based plastics. © www.indiegogo.com

The project is currently in the launching stage. On the Kickstarter platform, the campaign supporting the production of Kreis cups has already raised $22,000, surpassing the planned goal of $10,000. "We are collaborating with several coffee shops that are eager to provide us with used coffee grounds once we start production," shared Ricardo Garcia, Co-founder and Co-CEO of Coffee Kreis, with Daily Coffee News.

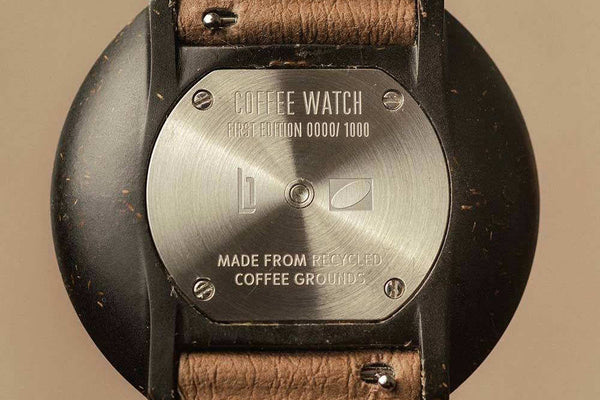

Coffee Watch — winner of the IF Design Award 2022 in the category of "Product Design - Watches and Jewelry." © www.kaffeeform.com

Utilization in gardening. Shane Genziuk from Melbourne introduces coffee lovers to the various ways of using coffee grounds in gardening, such as using them as plant fertilizers. He has created the Ground to Ground project, which identifies cafes that package their used coffee grounds and give them to visitors. In addition to Australia, he collaborates with partners from the United Kingdom and the United States. According to Shane's estimates, he has registered nearly a thousand coffee shops in his program.

Coating for icy streets. In Krakow, used coffee grounds are spread on sidewalks during winter as an alternative to sand-salt mixtures. The City Parks and Greenery Agency stated that the pilot program has received applications from more than 50 local coffee shops. Experts believe that besides combating ice, this material offers several other advantages. Coffee remnants, when used as fertilizers, are beneficial to the environment and less harmful to pets' paws. Additionally, it serves as an excellent promotional tool for coffee shops.

Coffee biofuel. Bio-bean is the world's largest coffee ground processor. In 2013, they launched a coffee collection service throughout the United Kingdom. Two years later, they built the world's first large-scale coffee ground processing plant. The plant processes approximately 55,000 tons of used coffee grounds per year, which is roughly 1/10 of the coffee waste generated in the United Kingdom. At the plant, the waste is transformed into biodiesel, charcoal for barbecues, and coffee pellets that serve as an alternative to wood fuel.

Flower pots in Manchester's public gardens. The London-based Hubbub Foundation has launched a simple, accessible, and creative program in Manchester. The issue at hand is that most disposable coffee cups are not recyclable due to the polyethylene lining. This has been a significant environmental drawback for the coffee industry for many decades.

The organization has placed 11 bin-shaped containers throughout the city as an environmentally friendly alternative to traditional waste bins. The partners of this project plan to repurpose the discarded coffee cups through the #1MoreShot program, transforming them into flower pots for public gardens. Preliminary estimates suggest that out of 20,000 coffee cups, 15,000 flower pots will be created.

The Manchester program has received support from Caffé Nero, Costa, Greggs, KFC, the Manchester City Council, McDonald's, Nestlé, Pret a Manger, and Waitrose. Hubbub representatives state that if the trial is successful, the program will be expanded to other markets.

The Future of Coffee Waste

As the coffee industry continues to grow, so does the generation of waste. For a considerable time, waste management has not received the attention it deserves. However, many major companies now view by-products not as trash but as raw materials for other processes. Depending on the type of coffee waste, numerous methods have already been devised for their further utilization, and each year brings forth an increasing number of new ideas and startups.